Rapid MOM

Our modular out of the box

Manufacturing Operations Management solution

for your shop floor

Rapid MOM

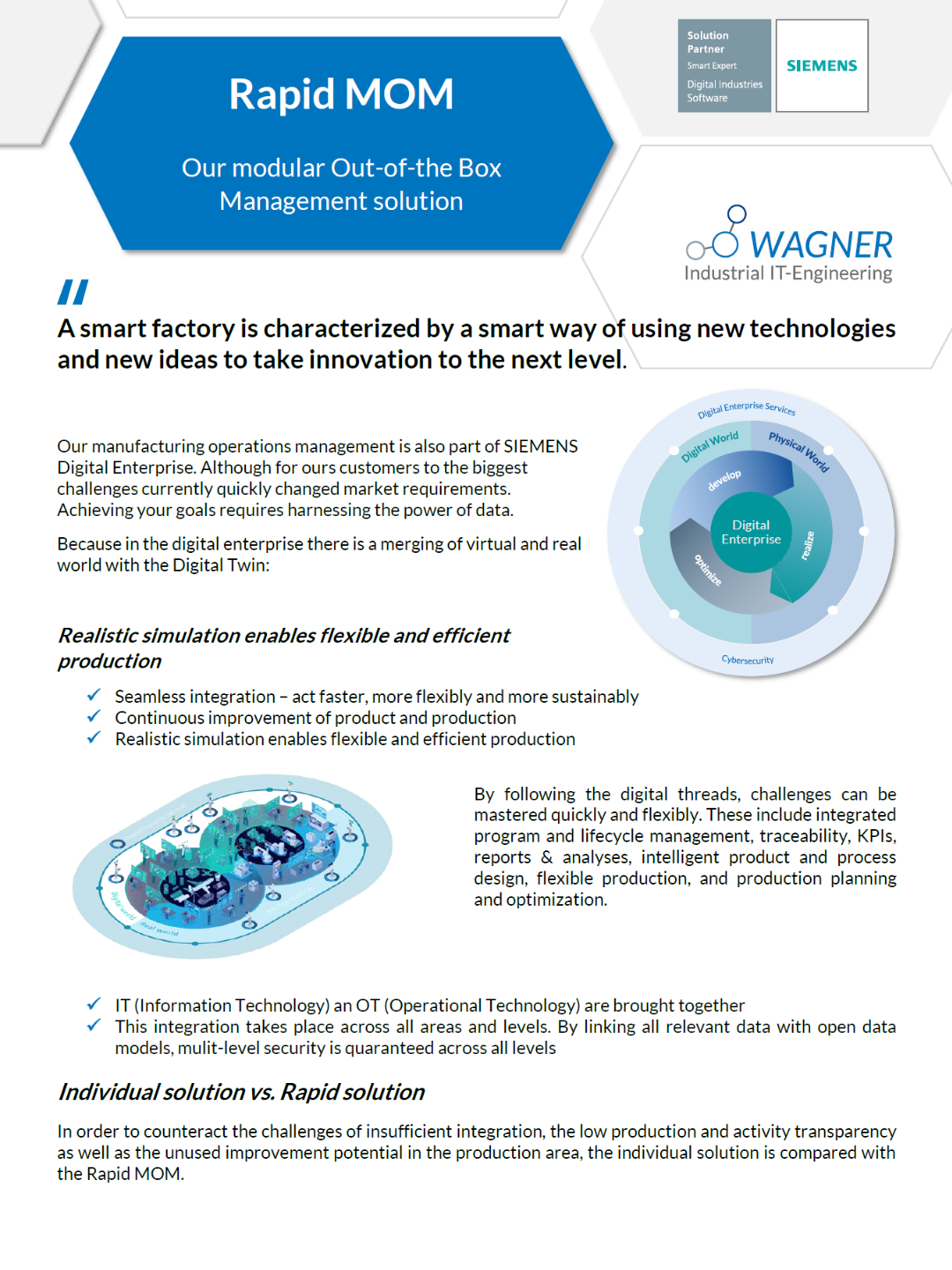

Our manufacturing operations management is also part of SIEMENS Digital Enterprise Achieving your goals requires harnessing the power of data.

In the digital enterprise, the virtual and real worlds merge into a “digital twin”:

Realistic simulation enables flexible and efficient production

By following the digital threads, challenges can be mastered quickly and flexibly. These include integrated program and life cycle management, traceability, KPIs, reports & analyses, intelligent product and process design, flexible production, and production planning and optimization.

- Seamless integration – act faster, more flexibly and more sustainably

- Continuous improvement of product and production

- Realistic simulation enables flexible and efficient production

Individual solution vs. rapid solution

In order to counteract the challenges of insufficient integration, the low production and activity transparency as well as the unused improvement potential in the production area, we select the standard in terms of best practices for quick and agile success. We use the synergies from experience to efficiently leverage potential.

ERP Integration

- Always up-to-date data -

- Timely synchronization of the data from the supply chain and shop floor data

- As a result, for example, material availability and stock levels are always up to date and time confirmations are process-specific within your ERP.

Detailed planning

- optimized production planning -

- Provision of the best possible operation sequences after comparison with production resources and restrictions and the ability to easily reschedule in the event of disruptions.

- Maximize the reliability of the production plan and plant availability while minimizing your lead times and delivery delays.

Paperless manufacturing

- Supporting worker guidance & complete production transparency -

- Supporting the worker by providing the required and up-to-date data in the correct form for the activity to be performed.

- This increases the quality of the work while reducing the training time at the same time and thus improves throughput times, system availability, product quality and the reject rate.

- Provision of a continuously traceable history of all activities carried out as part of the worker guidance.

- In the event of challenges such as complaints, this creates the possibility of quickly finding the cause in an uncomplicated manner.

Machine data acquisition

- Operational production monitoring -

- Real-time monitoring of the production facilities. Track the running times of your systems and calculate & monitor the most important key figures such as the OEE in self-configurable dashboards.

- These dashboards can also be embedded directly into the worker guidance.

- Provision of contextualized production information in a self-service analysis environment. Modern KPI dashboards support your decision-makers in making fact-based decisions at any time, regardless of device and role-based.

- You can also use this environment to carry out in-depth production analyzes and gain new insights to improve your production.

Production reporting

- Operational Reporting -

- The operational reporting reflects the most important current production key figures for your day-to-day business in tabular reports.

- You can easily create these reports yourself, and they support your day-to-day work with numbers, data and facts.

„Wagner Pre-Assessment“

Your first step with us

>>click here<<

Our services for you at a glance:

- System design + licensing

- Architecture + conception

- Process optimization

- Implementation

- System support

- Small projects and small prices